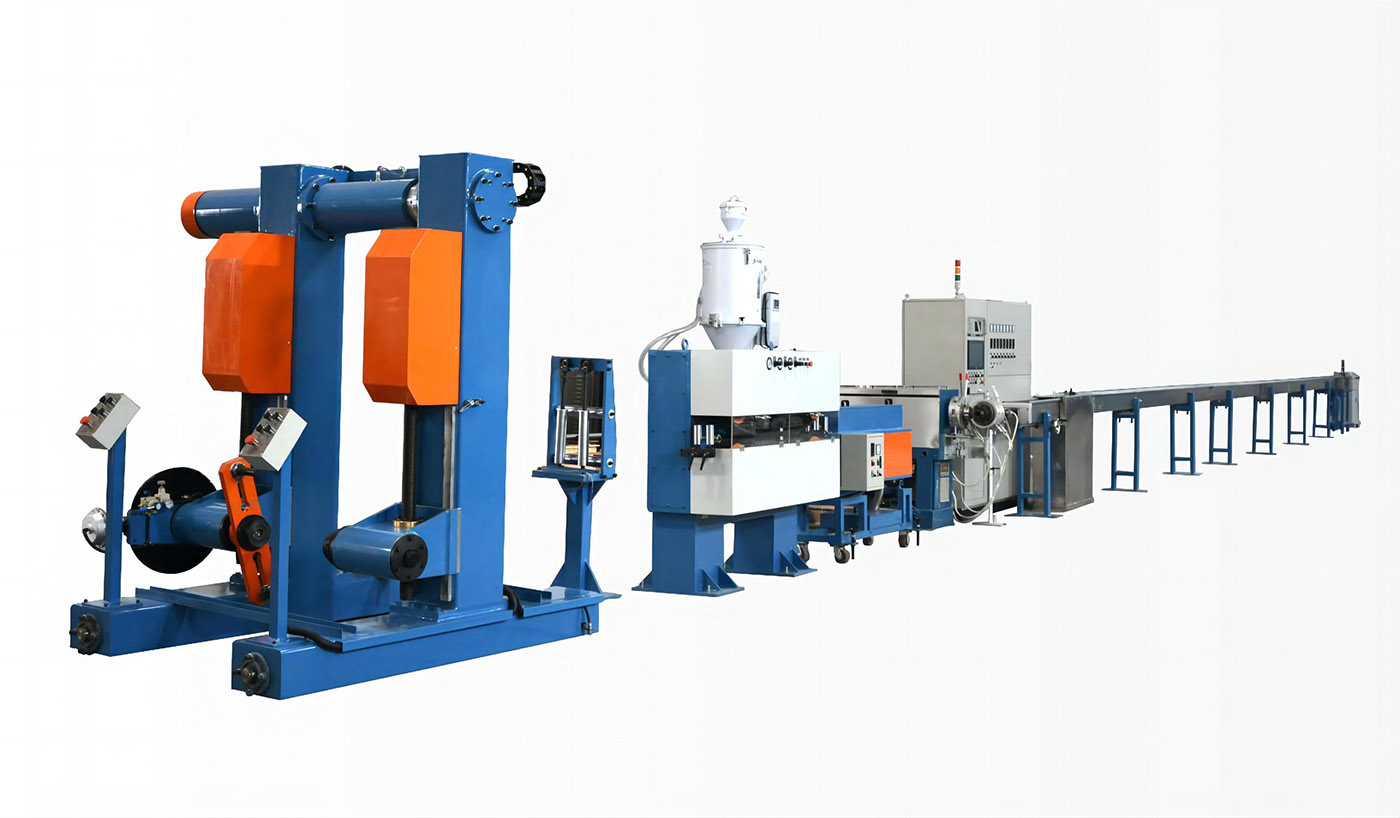

Kwintsimi yokwenziwa kweengcingo kunye nentambo, umgca wemveliso we-sheathing extrusion udlala indima ebalulekileyo. Kufana nokubeka idyasi eqinileyo yocingo kunye nentambo, ukukhusela i-conductor yangaphakathi kunye nomaleko wokugquma.

Okokuqala, makhe sihlalutye ngononophelo iiparitha zobugcisa kwitheyibhile. Iimodeli ezahlukeneyo zemigca yokuvelisa i-sheathing extrusion zibonisa imisebenzi eyahlukeneyo xa kusetyenzwa izixhobo ezahlukeneyo. Ngokomzekelo, umgca wokuvelisa imodeli ye-70 unamandla we-37KW, imveliso ye-180Kg / H, kunye nesantya esithile sokujikeleza xa kusenziwa izinto zePVC / LDPE; ngelixa xa kusetyenzwa izinto ze-MDPE / HDPE / XLPE, amandla abe yi-125KW, imveliso yi-37Kg / H, kwaye isantya sokujikeleza sikwahlukile; kwizinto ze-LSHF, amandla yi-75KW, imveliso yi-140Kg / H, kunye nesantya sokujikeleza yi-90rpm. Njengoko imodeli isanda, amandla, imveliso, kunye nesantya sokujikeleza sitshintsha ngokufanelekileyo ukuhlangabezana neemfuno ezahlukeneyo zemveliso kwizikali ezahlukeneyo.

Ngokujonga kwiindlela zokusetyenziswa komgca wemveliso we-sheathing extrusion ofundwe kwi-Intanethi, ubukhulu becala igubungela umphandle wocingo kunye nentambo ngokulinganayo ngemathiriyeli ethile ngeenkqubo ezinje ngokufudumeza kunye ne-extrusion ukwenza isingxobo esiqinileyo. Kule nkqubo, ukulawula ngokuchanekileyo iiparamitha zesixhobo kubalulekile. Izixhobo ezahlukeneyo zifuna ubushushu obahlukeneyo, uxinzelelo, kunye noseto lwesantya ukuqinisekisa umgangatho kunye nokusebenza kwesheath.

Ukujonga phambili kwimarike yexesha elizayo, kunye nophuhliso oluqhubekayo lweshishini lentambo kunye nentambo kunye nenkqubela phambili yetekhnoloji, ithemba lemarike lomgca wemveliso we-sheathing extrusion libanzi kakhulu. Kwelinye icala, njengoko imfuno yocingo kunye nentambo kumashishini ahlukeneyo iqhubeka nokukhula, iimfuno zomgangatho kunye nokusebenza kwesheath nazo ziya zinyuka nangaphezulu. Oku kuya kukhuthaza umgca wemveliso we-sheathing extrusion ukuba uqhubeke uphucula kwaye uphucule ukuhlangabezana nemigangatho ephezulu yemveliso. Umzekelo, phucula inqanaba lokuzenzekela kwesixhobo, ukufikelela kulawulo oluchanekileyo lweparamitha, kunye nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Kwelinye icala, ukusetyenziswa kwezinto ezinobungani nokusingqongileyo kuya kuba yindlela yophuhliso yexesha elizayo. Umgca wemveliso we-sheathing extrusion kufuneka ulungelelanise iimfuno zokusetyenzwa kwezinto ezintsha ezihambelana nokusingqongileyo kwaye zibonelele ngakumbi ngokusingqongileyo kunye neeshethi ezizinzileyo zocingo kunye nentambo.

Kwiifektri zentambo, imfuno yemigca yokuvelisa i-sheathing extrusion ibonakala ikakhulu kule miba ilandelayo. Okokuqala, izixhobo kufuneka zibe nomthamo osebenzayo wokuvelisa ukuhlangabezana neemfuno zemveliso enkulu. Izixhobo ezinamandla amakhulu kunye nemveliso ephezulu inokuvelisa iimveliso ezininzi ngexesha leyunithi kunye nokuphucula ukusebenza kakuhle kwemveliso. Okwesibini, kuyafuneka ukuba izixhobo ziqinisekise umgangatho ozinzileyo we-sheath. Ukulawulwa kwesantya esichanekileyo kunye nemimiselo yeparameter yenkqubo enokuqinisekisa ukuba i-sheath inobunzima obufanayo kunye nokusebenza okuthembekileyo. Ukongeza, iifektri zekhebula nazo zilindele ukuba izixhobo zibe neendleko zokugcinwa okuphantsi kunye nokuthembeka okuphezulu ukunciphisa umngcipheko wokuphazamiseka kwemveliso.

Ngokubhekiselele kwisantya sokusebenza kwezixhobo, iimodeli ezahlukeneyo zemigca yokuvelisa i-sheathing extrusion inezantya ezahlukeneyo zokujikeleza. Oku kunika ukhetho oluninzi lweefektri zekhebula, kunye nesantya sokusebenza kwesixhobo sinokuhlengahlengiswa ngokuhambelana nokukhawuleza kwemisebenzi yokuvelisa kunye neemfuno zokucaciswa kwemveliso. Kwangaxeshanye, kunye nenkqubela phambili yobugcisa, umgca wemveliso we-sheathing extrusion wexesha elizayo kulindeleke ukuba unyuse ngakumbi isantya sokusebenza kunye nokunciphisa umjikelo wemveliso kwisiseko sokugcina imveliso ekumgangatho ophezulu.

Ukuqukumbela, njengesixhobo esibalulekileyo sokwenziwa kweengcingo kunye neentambo, umgca wemveliso we-sheathing extrusion ubaluleke kakhulu ngokwemilinganiselo yobugcisa, iindlela zokusetyenziswa, iimarike zexesha elizayo, kunye neemfuno zefektri yentambo. Iza kuqhubeka nokuphuhlisa nokusungula izinto ezintsha kunye nokubonelela ngezisombululo ezikumgangatho ophezulu kunye nezisebenzayo zokuvelisa i-sheathing kwishishini lecingo kunye nentambo kunye nokubeka idyasi eyomeleleyo ngakumbi yocingo kunye nentambo.

Ixesha lokuposa: Sep-27-2024